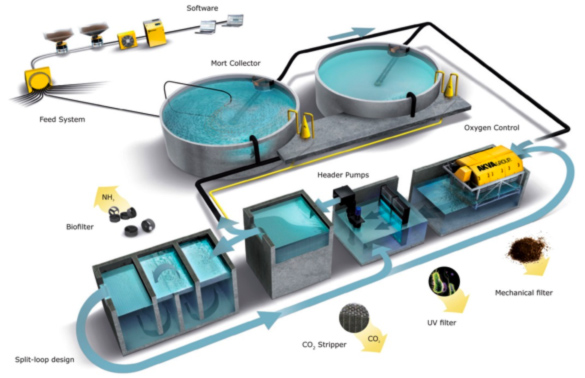

AKVA split loop RAS system

RAS offers the advantage that temperature and other variables can be controlled, in order to maximise growth and maintain fish health. Recirculating systems also require much less incoming water, some newer plants require only approx. 1 – 5%, compared to flow through farms, minimising the discharge to the environment and allowing operations to be established even where water supplies are quite small.

All modern RAS systems generally have the following components;

Often it is necessary for several of these components to be combined (i.e. biofilter, carbon dioxide degasser, nitrate filter and foam fractionation) for simplicity and capital savings. The resulting system is however generally compromised.

There are many ways to build a RAS system and no “one way” can be said to be best across all species, budgets and situations. The choice of best system for a particular application must be based on:

In the schematic below showing one possible RAS design, to keep electrical costs low all pipe work is designed to minimise head-loss e.g. pipes not limited in diameter and length and all bends are curved and not sharp elbows. Water is pumped from the sump to the tanks (via a disinfectant unit and the bio-filter) with either an aeration or oxygenation step on the way. Water then flows by gravity to the drum filter before returning to the sump. Often, a second small pump draws water from the sump and passes the water through a foam fractionator (protein skimmer) and returns the water via gravity to the sump.

Schematic of generic RAS system (A)

Schematic of generic RAS system (B)

Schematic of generic RAS system (C)

To increase the efficiency of carbon dioxide removal in modern high load RAS systems, a second high flow volume loop is often installed parallel to the bio-filter (called a split loop). This is because bio-filters work more efficiently with low to moderate flows but high flows are required to flush carbon dioxide from the rearing tanks and supply oxygen when stocking biomass per cubic meter is high (i.e. over 70kg/cu.m. but this depends on species).

Commercial Billund Aquaculture fingerling RAS facility

Goldbill (Chinese) “off the shelf” RAS system

Commercial Billund Aquaculture growout RAS system

Commercial Billund Aquaculture RAS water treatment systems

There is limited information, within the New Zealand context with NZ species, to give any reliable costs and potential returns for intensive recirculating (RAS) farming systems. Many commercial RAS farms are established overseas and their use is increasing rapidly. This is an indication that well designed and well managed systems can be both economically and environmentally sustainable.

The following table taken from the Danish trout (Rainbow trout in brackish 20ppt water) RAS farming industry indicates the approximate relative costs of inputs to trout farming (based on a 1000T per annum production unit). The overall production cost was equivalent to NZ$ 4-5/kg.

|

Input |

PERCENT(%) |

|---|---|

|

Feed |

50.2 |

|

Electricity |

7.9 |

|

Oxygen |

4.8 |

|

Chemicals/vaccines |

1.3 |

|

Juveniles |

1.3 |

|

Labour |

10.1 |

|

Maintenance |

1.3 |

|

Administration |

2.6 |

|

Licences etc |

0.9 |

|

Cost of capital (15%) |

19.7 |

NPFL has produced a number of RAS economic models based on promising species that can be farmed in New Zealand.

These models are available for download here.

tel. +56 65 2229706

mob. +56 9 747 84 009

+64-9-432-5521